Introduction: Why Proper Touchscreen Maintenance Matters

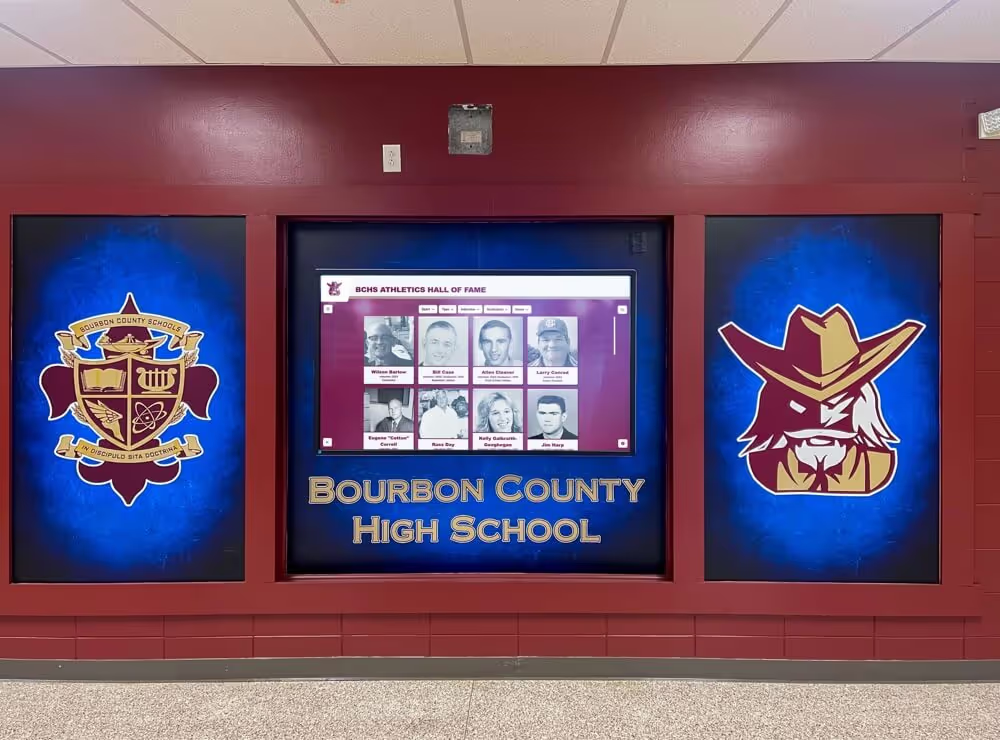

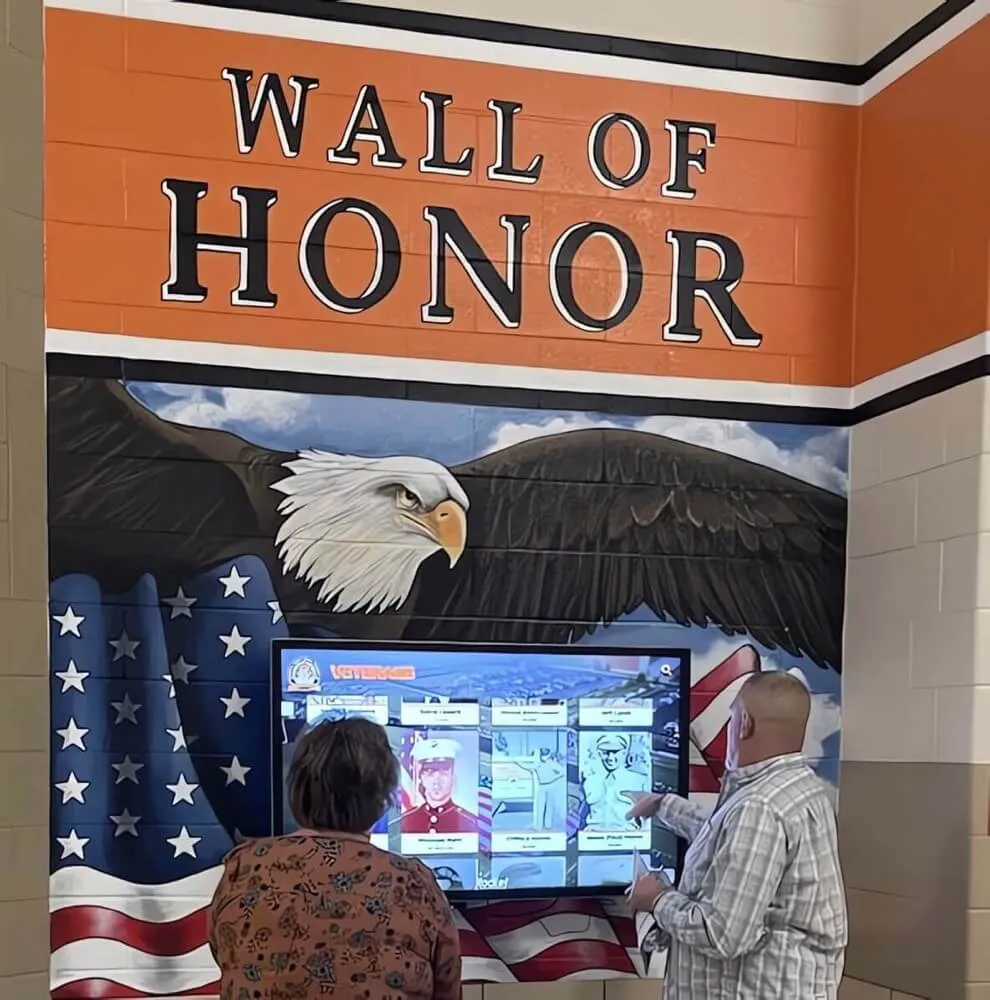

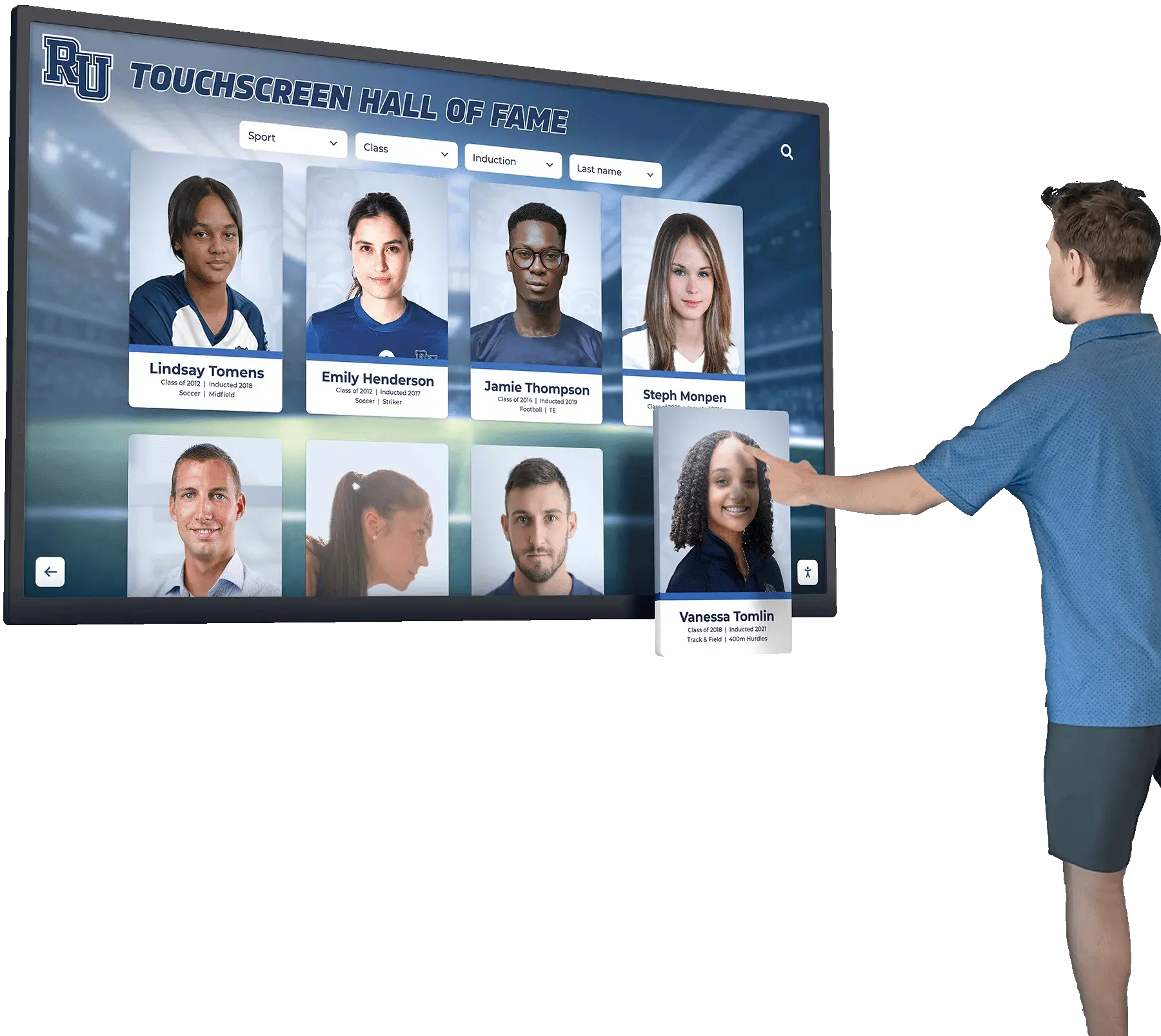

After investing thousands of dollars in a professional digital hall of fame or interactive touchscreen display, proper maintenance ensures your system delivers years of reliable performance while maintaining a pristine appearance. Inadequate cleaning protocols and neglected maintenance routines lead to premature hardware failure, degraded user experience, and costly emergency repairs.

High-traffic touchscreen installations face unique challenges: constant touching transfers oils, dirt, and germs to screens; continuous operation stresses hardware components; and environmental factors like dust, humidity, and temperature fluctuations affect performance. This comprehensive guide provides expert protocols for cleaning, maintaining, and troubleshooting interactive touchscreen displays, ensuring your digital recognition system continues engaging visitors effectively.

Understanding Touchscreen Technology and Maintenance Requirements

Different touchscreen technologies require specific maintenance approaches to avoid damage while maximizing longevity and performance.

Capacitive Touchscreen Care

Capacitive touchscreens—the same technology used in smartphones—detect electrical properties of your finger through a transparent electrode layer. These screens provide exceptional responsiveness but require careful cleaning to protect their delicate surfaces.

Maintenance Characteristics:

- Glass surface resists scratching but can accumulate fingerprint oils

- Anti-fingerprint coatings gradually degrade with aggressive cleaning

- Edge sensors require occasional recalibration for accuracy

- Electrostatic discharge (ESD) sensitivity demands proper grounding

Cleaning Protocol:

- Use only approved screen cleaners (70% isopropyl alcohol or less)

- Apply cleaner to microfiber cloth, never directly to screen

- Wipe in gentle circular motions without applying pressure

- Allow complete drying before powering on (minimum 2 minutes)

- Never use ammonia-based cleaners (Windex, generic glass cleaners)

Infrared Touchscreen Maintenance

Infrared touchscreens use light beams across the display surface to detect touch points when fingers interrupt the beam pattern. While mechanically durable, infrared frames require specific care to maintain accuracy.

Maintenance Characteristics:

- Raised bezel around screen perimeter houses infrared emitters and receivers

- Dust accumulation in bezel area creates false touch registration

- No overlay means excellent optical clarity that won’t degrade

- Works with gloves, styluses, and bare fingers

Cleaning Protocol:

- Clean screen surface using standard LCD cleaning methods

- Carefully clean infrared bezel area with compressed air

- Use cotton swabs dampened with isopropyl alcohol for bezel cleaning

- Inspect for insects or debris trapped in bezel channels

- Recalibrate touch system after thorough cleaning

For organizations implementing touchscreen kiosk solutions, understanding your specific hardware helps develop appropriate maintenance procedures.

Daily Cleaning and Inspection Protocols

Consistent daily maintenance prevents minor issues from becoming major problems while keeping displays looking professional and performing optimally.

Morning Pre-Opening Inspection

Visual Assessment Checklist:

Display Quality Verification:

- Check for overnight system crashes or frozen screens

- Verify brightness levels appear consistent

- Look for dead pixels, discoloration, or image retention

- Confirm content displays correctly without glitches

- Test basic touch responsiveness in multiple screen areas

Physical Condition Review:

- Inspect screen for cracks, scratches, or damage

- Check mounting hardware for stability and security

- Verify cables remain securely connected

- Look for dust accumulation on vents and surfaces

- Confirm kiosk enclosure remains undamaged

This inspection typically requires 3-5 minutes per display and prevents visitors from encountering non-functional systems.

Surface Cleaning Routine

Proper Daily Cleaning Procedure:

- Power Down Display: Always turn off display before cleaning to prevent electrical issues and to better see dirt and smudges against black screen

- Dust Removal: Use dry microfiber cloth to remove loose dust and particles before wet cleaning

- Screen Cleaning: Apply approved cleaning solution to clean microfiber cloth (never spray directly on screen)

- Gentle Wiping: Clean in gentle S-pattern motions from top to bottom, using light pressure

- Dry Buffing: Use second dry microfiber cloth to remove any remaining moisture and prevent streaking

- Bezel Cleaning: Wipe down bezel and surrounding surfaces with dampened cloth

- Final Inspection: Verify screen appears clean and streak-free before powering on

Cleaning Solution Guidelines:

Approved cleaning solutions for touchscreen displays:

- 70% isopropyl alcohol (or less) solution

- Distilled water with small amount of white vinegar (10:1 ratio)

- Commercial screen cleaning solutions labeled safe for touch displays

- Manufacturer-approved proprietary cleaners

Never use these harmful substances:

- Ammonia-based glass cleaners

- Abrasive cleaners or scrubbing compounds

- Bleach or harsh chemicals

- Paper towels (create micro-scratches)

- Excessive water or liquid (causes damage to electronics)

Traffic-Based Cleaning Frequency

Low-Traffic Environments (< 50 touches/day):

- Quick wipe-down: Once daily

- Deep cleaning: Weekly

- Examples: Staff lounges, small museums, private clubs

Medium-Traffic Environments (50-200 touches/day):

- Quick wipe-down: 2-3 times daily

- Deep cleaning: Twice weekly

- Examples: School lobbies, small corporate offices

High-Traffic Environments (200-500 touches/day):

- Quick wipe-down: 4-5 times daily

- Deep cleaning: Daily

- Examples: Large schools, busy athletic facilities

Very High-Traffic Environments (500+ touches/day):

- Quick wipe-down: Every 2-3 hours

- Deep cleaning: Twice daily

- Examples: Airports, major museums, large event venues

Organizations managing interactive recognition displays in schools and public facilities typically fall into high-traffic categories requiring frequent attention.

Weekly Maintenance Tasks and System Health Checks

Weekly maintenance extends beyond surface cleaning to address system performance, security updates, and environmental factors affecting display longevity.

Comprehensive System Performance Assessment

Software Health Verification:

- Application Performance: Launch and test all user-facing features and navigation paths

- Content Loading Speed: Verify images, videos, and data load within acceptable timeframes (< 2 seconds)

- Touch Accuracy Testing: Test touch response across all screen quadrants and edge areas

- Memory Usage: Check system resource utilization to identify memory leaks or bloated processes

- Error Log Review: Examine system logs for recurring errors, warnings, or crash reports

Network Connectivity Testing:

Reliable network connectivity ensures your content management system functions properly:

- Test internet connection speed (minimum 10 Mbps download, 2 Mbps upload)

- Verify consistent network signal strength (Wi-Fi should exceed -67 dBm)

- Check for packet loss or latency issues affecting content updates

- Confirm VPN or secure connection functionality

- Test remote management access and control

Security and Update Management:

Operating System Maintenance:

- Install pending OS security patches and updates

- Review and apply firmware updates for display hardware

- Update graphics drivers to latest stable versions

- Clean temporary files and system caches

- Defragment storage drives (HDD systems only)

Application Updates:

- Update display software and content management systems

- Apply security patches to all installed applications

- Test applications after updates to verify functionality

- Update antivirus definitions and run full system scan

- Review user access permissions and remove inactive accounts

Consistent updates protect against security vulnerabilities while ensuring compatibility with evolving technologies used in digital record boards and recognition systems.

Environmental Monitoring and Climate Control

Temperature, humidity, and dust significantly impact display lifespan and reliability:

Optimal Environmental Conditions:

| Environmental Factor | Optimal Range | Monitoring Method | Action Threshold |

|---|---|---|---|

| Temperature | 68-72°F (20-22°C) | Digital thermometer | Alert at 65°F or 75°F |

| Relative Humidity | 45-55% RH | Hygrometer | Alert at 40% or 60% |

| Dust Accumulation | Minimal visible dust | Visual inspection | Clean when visible |

| Ambient Light | < 500 lux on screen | Light meter | Adjust brightness settings |

| Air Circulation | Adequate ventilation | Airflow check | Clean vents quarterly |

Climate-Related Maintenance Actions:

- High Temperature: Verify HVAC function, check display cooling fans, ensure unobstructed air vents

- Low Temperature: Check for condensation risk, verify heating system, monitor for cold-start issues

- High Humidity: Run dehumidifier, check for condensation inside display, inspect cable connections

- Low Humidity: Use humidifier, apply anti-static spray around display, verify ESD protection

- Excessive Dust: Increase cleaning frequency, install air filters, seal enclosure gaps

Monthly Deep Maintenance and Hardware Inspection

Monthly maintenance addresses components requiring less frequent attention but critical for long-term reliability and performance.

Internal Hardware Component Inspection

Media Player and Computer Maintenance:

Access internal components (with proper permissions and documentation) for thorough inspection:

- Dust Removal: Use compressed air to clean internal fans, heat sinks, and component surfaces

- Cable Management: Verify all internal cables remain securely connected and properly routed

- Thermal Paste: Check CPU/GPU temperatures; replace thermal paste annually if temps exceed specifications

- Storage Health: Run SMART diagnostics on SSDs/HDDs to identify failing drives before catastrophic failure

- RAM Testing: Run memory diagnostics to identify failing modules causing crashes or slowdowns

- Power Supply: Listen for unusual noises, check for bulging capacitors, verify voltage outputs

Display Panel Inspection:

- Examine panel edges for light bleed or separation from frame

- Check backlight uniformity across entire screen surface

- Test for image retention or temporary burn-in (static content displays)

- Verify color accuracy and consistency using test patterns

- Inspect for pixel issues (stuck, dead, or hot pixels)

For institutions maintaining multiple displays across campus locations, developing standardized inspection checklists ensures consistent care as described in hardware selection guides.

Mounting Hardware and Physical Security Review

Mounting System Verification:

Wall-Mounted Displays:

- Check wall anchor security and integrity

- Verify mounting bracket bolts remain tight

- Inspect wall surface for cracks or deterioration

- Test display stability with gentle pressure

- Examine cable routing and strain relief

- Verify anti-theft security screws intact

Floor Kiosk Enclosures:

- Check floor anchor security and stability

- Inspect enclosure panels for damage or wear

- Verify access door locks function properly

- Test kiosk stability with gentle rocking

- Examine touchscreen mounting security

- Inspect power and data cable protection

Proper mounting ensures safety while protecting your investment in interactive touchscreen software and hardware.

Backup Verification and Disaster Recovery Testing

Comprehensive Backup Strategy:

Content and Configuration Backups:

- Verify automated backup systems completed successfully

- Test backup restoration process on non-production system

- Confirm backup files stored in geographically diverse locations

- Document backup retention periods and archive procedures

- Verify backup encryption and access controls

System Recovery Procedures:

- Create system restore points before major updates

- Maintain bootable recovery media updated with current OS version

- Document system configuration and settings for rapid rebuilding

- Test recovery procedures annually to verify effectiveness

- Train multiple staff members on recovery processes

Organizations managing critical displays for donor recognition and institutional history cannot afford extended downtime due to inadequate backup procedures.

Quarterly Maintenance: Professional Service and Calibration

Quarterly maintenance represents the most comprehensive service interval, often requiring professional expertise or specialized equipment.

Professional Cleaning and Servicing

Complete System Teardown Cleaning:

Professional service provides cleaning impossible during routine maintenance:

- Remove display from mounting hardware for complete access

- Clean rear ventilation areas and electronic component surfaces

- Service internal fans with bearing lubrication or replacement

- Clean display panel edges and bezel attachment points

- Inspect and clean all cable connections and ports

- Reassemble with proper torque specifications and procedures

Calibration Services:

Touchscreen Calibration:

- Multi-point touch accuracy verification and adjustment

- Pressure sensitivity optimization

- Edge responsiveness calibration

- Multi-touch gesture testing and refinement

- Ghost touch detection and elimination

Display Calibration:

- Color accuracy calibration to industry standards

- Brightness and contrast optimization

- Gamma curve adjustment

- White balance calibration

- Backlight uniformity verification

Professional calibration ensures optimal performance for digital scholarship recognition boards and other high-visibility applications requiring exceptional presentation quality.

Performance Optimization and Capacity Planning

System Performance Tuning:

Quarterly reviews identify performance degradation requiring intervention:

- Storage Optimization: Remove unnecessary files, defragment drives, consolidate data

- Application Optimization: Remove unused applications, disable unnecessary startup programs

- Network Optimization: Update network drivers, optimize TCP/IP settings, test bandwidth

- Memory Management: Identify and eliminate memory leaks, upgrade RAM if needed

- Graphics Optimization: Update drivers, adjust settings for optimal performance

Capacity Planning and Upgrade Assessment:

Review system capabilities against current and future requirements:

- Storage Capacity: Project storage needs for next 12-24 months based on growth trends

- Processing Power: Assess whether current hardware adequately supports software demands

- Memory Requirements: Determine if RAM upgrades would improve performance

- Network Bandwidth: Evaluate whether connection speed meets current and projected needs

- Display Technology: Consider whether display resolution, size, or refresh rate meets expectations

For organizations implementing recognition solutions that evolve over time, proactive capacity planning prevents performance bottlenecks.

Hygiene Best Practices for Public Touchscreens

Public health consciousness has elevated hygiene importance for shared touchscreen surfaces. Implementing effective sanitation protocols protects users while maintaining equipment integrity.

Disinfection Protocols and Approved Cleaners

Touchscreen-Safe Disinfectants:

Not all disinfectants are safe for touchscreen surfaces. Approved solutions include:

Recommended Disinfectants:

- 70% isopropyl alcohol wipes (pre-moistened or DIY)

- Quaternary ammonium compound wipes (verify touchscreen compatibility)

- Hydrogen peroxide solution (3% concentration or less)

- Commercial touchscreen-safe disinfectant wipes

- UV-C sanitizing devices (contact-free disinfection)

Prohibited Disinfectants:

- Bleach solutions (damages anti-reflective coatings)

- Ammonia-based cleaners (etches screen surface)

- Abrasive disinfectant powders or scrubs

- Alcohol concentrations exceeding 70% (damages oleophobic coatings)

- Phenolic disinfectants (causes yellowing and damage)

Disinfection Procedure:

- Power down display to prevent electrical issues and improve visibility

- Use touchscreen-safe disinfectant wipe or apply solution to microfiber cloth

- Wipe entire touchable surface using overlapping strokes

- Allow recommended contact time for disinfectant effectiveness (typically 30-60 seconds)

- Wipe surface with clean, dry microfiber cloth to remove residue

- Allow complete drying (minimum 2 minutes) before powering on

- Wash hands after completing cleaning procedure

Automated Sanitization Solutions

Touchless Sanitization Technologies:

Advanced solutions reduce manual cleaning requirements while maintaining hygiene:

UV-C Sanitization Systems:

- Automated UV-C light exposure during idle periods

- 99.9% pathogen reduction in 30-60 seconds

- No chemical residue or surface degradation

- Requires safety interlocks preventing user exposure

- Annual bulb replacement required

Antimicrobial Screen Coatings:

- Silver ion or copper-infused surface treatments

- Continuous antimicrobial protection

- 99% pathogen reduction within 2 hours

- Lasts 6-12 months before reapplication needed

- Compatible with most touchscreen technologies

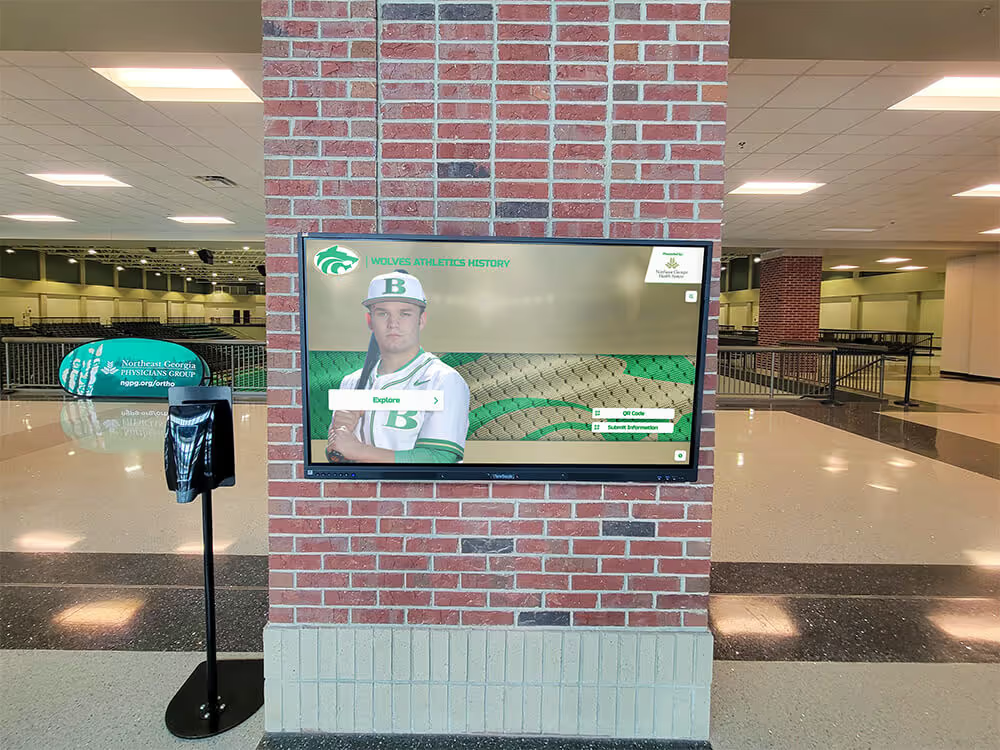

Hand Sanitizer Station Integration:

Mounting hand sanitizer dispensers adjacent to touchscreen displays encourages users to sanitize before and after interaction:

- Position dispenser 12-18 inches from touchscreen at comfortable height

- Use touchless dispensers to avoid creating additional contamination point

- Ensure sanitizer formula compatible with touchscreens (avoid moisturizing additives)

- Refill dispensers weekly or more frequently in high-traffic areas

- Post signage encouraging sanitizer use

These hygiene measures protect visitors using interactive hall of fame displays while demonstrating organizational commitment to health and safety.

Troubleshooting Common Touchscreen Issues

Even well-maintained touchscreens occasionally experience issues requiring troubleshooting expertise to restore functionality quickly.

Touch Responsiveness Problems

Symptom: Unresponsive or Inaccurate Touch Detection

Common Causes and Solutions:

Dirty or Contaminated Screen:

- Solution: Thoroughly clean screen with approved cleaner

- Remove any protective film not designed for touchscreens

- Check for moisture or cleaning solution residue

- Allow complete drying before retesting

Calibration Drift:

- Solution: Recalibrate touchscreen using built-in tools

- Run multi-point calibration procedure

- Test accuracy across entire screen surface

- Document calibration dates for pattern identification

Connection Issues:

- Solution: Check USB or controller cable connections

- Reseat cables at both display and computer ends

- Test with different USB port

- Replace damaged cables

Driver or Software Problems:

- Solution: Update touchscreen drivers to latest version

- Reinstall drivers if update doesn’t resolve issue

- Check for software conflicts with recently installed programs

- Roll back recent updates if problems started after update

Symptom: Ghost Touches or Phantom Input

Ghost touches occur when touchscreen registers input without physical contact:

Diagnostic Steps:

- Clean screen thoroughly to remove moisture or contaminants

- Inspect infrared bezels (if applicable) for debris or insect presence

- Check for electromagnetic interference from nearby equipment

- Verify proper grounding of display and computer

- Test in isolation from other equipment to identify interference sources

- Replace touchscreen controller if hardware failure suspected

Display Quality Issues

Symptom: Flickering or Unstable Image

Possible Causes:

- Loose or damaged video cable connections

- Incompatible refresh rate settings

- Graphics driver issues

- Insufficient or unstable power supply

- Backlight inverter failure (LCD panels)

- Display panel degradation

Troubleshooting Steps:

- Verify all video cables securely connected

- Test with different video cable

- Update graphics card drivers

- Check power supply voltage stability

- Test with different power outlet

- Replace display if panel failure confirmed

Symptom: Dead Pixels or Image Persistence

Dead pixels appear as black, white, or colored spots that don’t change:

Dead Pixel Assessment:

- 1-5 dead pixels: Normal for modern displays, typically acceptable

- 6-10 dead pixels: Borderline; may qualify for warranty replacement

- 10+ dead pixels: Definitely warrants warranty replacement

- Clustered dead pixels: More noticeable than scattered; prioritize replacement

Image Persistence (Temporary Burn-In):

- Run pixel-refreshing software overnight

- Display shifting content (screensaver with motion) for 24-48 hours

- Adjust content management to avoid static elements in same position

- Implement automatic screen rotation or content shifting features

For displays experiencing persistent technical issues, consulting with professional services supporting digital hall of fame implementations ensures proper diagnosis and repair.

Seasonal Maintenance Considerations

Seasonal environmental changes create unique challenges requiring adapted maintenance approaches throughout the year.

Spring Maintenance Priorities

Spring brings increased humidity, pollen, and temperature fluctuations requiring specific attention:

Post-Winter Deep Cleaning:

- Thoroughly clean accumulated winter dust from all surfaces

- Inspect for condensation damage from heating system proximity

- Verify HVAC transition from heating to cooling mode

- Check external ventilation areas for obstruction

- Update content for new academic or fiscal year

Humidity Management:

- Monitor increased humidity levels from spring weather

- Run dehumidifiers in display areas if humidity exceeds 60%

- Check for condensation inside displays during temperature swings

- Inspect cable connections for corrosion from moisture

- Apply dielectric grease to exposed connectors

Summer Maintenance Priorities

Summer heat stresses cooling systems while providing opportunities for major maintenance during reduced usage periods:

Cooling System Verification:

- Clean air filters and intake vents thoroughly

- Verify internal fans operate at proper speeds

- Monitor internal temperatures during peak heat periods

- Ensure adequate clearance around displays for airflow

- Consider supplemental cooling for inadequately climate-controlled spaces

Planned Downtime Activities:

- Schedule major software updates during summer breaks

- Perform comprehensive hardware inspection and servicing

- Replace aging components before failure during busy season

- Refresh content for upcoming academic or calendar year

- Provide staff training on new features or procedures

Fall Maintenance Priorities

Fall preparation ensures systems ready for increased usage during busy school or business seasons:

Pre-Season Preparation:

- Test all systems under load before peak usage periods

- Verify content management workflows and approval processes

- Refresh staff training on routine maintenance procedures

- Stock cleaning supplies and spare parts

- Update emergency contact information and support procedures

HVAC Transition Management:

- Monitor heating system activation for heat damage to displays

- Check for static electricity issues as humidity drops

- Inspect for dust circulation from heating system startup

- Adjust display brightness for changing natural light levels

- Verify backup power systems before winter storm season

Winter Maintenance Priorities

Winter challenges include heating effects, reduced humidity, static electricity, and potential weather-related issues:

Heating and Humidity Concerns:

- Monitor very low humidity levels (below 35%) causing static issues

- Run humidifiers near displays to maintain 45% minimum humidity

- Apply anti-static spray to surrounding surfaces

- Ground touchscreen frames to prevent ESD damage

- Increase cleaning frequency as heating systems circulate dust

Cold Weather Preparation:

- Develop emergency procedures for extended power outages

- Verify UPS battery backup systems functional

- Protect displays in unconditioned spaces from freezing temperatures

- Monitor cold-start performance in spaces with nighttime temperature setback

- Plan content updates around holiday closures

Organizations maintaining sports record boards and recognition displays through all seasons benefit from proactive seasonal maintenance planning.

Professional Maintenance Services and Support Plans

While internal teams handle routine maintenance effectively, professional services provide expertise, equipment, and support beyond typical organizational capabilities.

When to Engage Professional Services

Situations Requiring Professional Expertise:

Hardware Failures:

- Display panel backlight failure

- Touch sensor malfunction requiring replacement

- Media player or computer hardware failure

- Power supply issues beyond simple replacements

- Physical damage requiring panel replacement

Complex Technical Issues:

- Persistent software conflicts and crashes

- Network integration and security configuration

- Multi-display synchronization problems

- Advanced calibration requiring specialized equipment

- Performance degradation despite optimization efforts

Preventive Professional Services:

- Annual comprehensive inspection and servicing

- Display calibration using professional colorimeters

- Environmental monitoring system installation

- Upgrade and expansion project implementation

- Staff training on advanced maintenance procedures

Warranty and Compliance:

- Warranty-covered repairs and replacements

- Manufacturer-required service for warranty maintenance

- Compliance audits for accessibility standards

- Safety inspections for public installations

- Documentation for institutional records

Service Provider Selection Criteria:

Evaluate maintenance service providers using these factors:

- Manufacturer authorization and certification credentials

- Response time commitments for emergency service calls

- Local technician availability and service area coverage

- Spare parts inventory and supply chain relationships

- Experience with your specific hardware and software platforms

- Service contract flexibility and pricing transparency

- Customer references from similar organizations

Companies like Rocket Alumni Solutions provide comprehensive maintenance support specifically designed for educational and institutional recognition displays, offering expertise beyond generic IT service providers.

Maintenance Service Packages and Pricing

Typical Service Level Options:

Basic Support Package ($1,200-2,400/year):

- Remote monitoring and diagnostic services

- Software updates and security patches

- Email and phone support during business hours

- One annual on-site preventive maintenance visit

- Documentation and maintenance logs

- Standard response time (24-48 hours)

Comprehensive Care Package ($2,400-4,800/year):

- Quarterly on-site preventive maintenance visits

- Priority phone and email support

- Hardware replacement coverage (parts only)

- Performance optimization and tuning

- Semi-annual calibration services

- Expedited response time (4-8 hours)

Premium Protection Package ($4,800-9,600/year):

- Monthly on-site maintenance and inspection visits

- 24/7 emergency support hotline

- Full hardware replacement coverage (parts and labor)

- Dedicated account manager assignment

- Advanced analytics and reporting

- Same-day response time commitment

Cost-Benefit Analysis:

Professional maintenance services protect investments while reducing total cost of ownership:

Five-Year Comparison: DIY vs. Professional Maintenance

DIY Maintenance Approach:

Internal staff time: $3,000/year × 5 = $15,000

Supplies and materials: $800/year × 5 = $4,000

Emergency repair average: $3,000 × 2 incidents = $6,000

Unplanned downtime costs: $5,000

Total Five-Year Cost: $30,000

Professional Comprehensive Care:

Annual service contract: $3,600/year × 5 = $18,000

Minimal internal staff time: $500/year × 5 = $2,500

Included repairs and parts: $0

Reduced downtime: $500

Total Five-Year Cost: $21,000

Savings with Professional Service: $9,000 over five years

Additional Benefits: Expert care, warranty compliance, peace of mind

Organizations managing critical installations for alumni engagement and institutional identity increasingly recognize professional maintenance value.

Documentation and Record Keeping Best Practices

Comprehensive maintenance documentation enables pattern recognition, warranty compliance, informed decision-making, and knowledge transfer between staff members.

Essential Maintenance Documentation

Daily Maintenance Logs:

Create standardized forms capturing critical information:

- Date, time, and person performing maintenance

- Visual inspection results and anomalies observed

- Cleaning procedures performed and products used

- Touch responsiveness testing results

- Content verification and update confirmations

- Any user-reported issues addressed

Incident and Repair Records:

Document all issues and resolutions thoroughly:

- Detailed problem description and symptoms observed

- Troubleshooting steps attempted before resolution

- Root cause analysis and corrective actions taken

- Parts replaced with serial numbers and specifications

- Service provider information if external help required

- Downtime duration and business impact

- Follow-up actions required and completion status

Service History Database:

Maintain comprehensive historical records for each display:

- Original purchase information and warranty details

- Installation date and configuration documentation

- All maintenance activities performed throughout lifecycle

- Hardware and software upgrade history

- Calibration dates and results

- Performance metrics and trend data

- Total cost of ownership tracking

Warranty Compliance and Claims

Maintaining Warranty Coverage:

Manufacturer warranties typically require documentation proving proper maintenance:

- Follow manufacturer-specified maintenance schedules exactly

- Use only approved cleaning products and procedures

- Document all maintenance activities with dates and details

- Retain professional service records from authorized providers

- Photograph any damage or failures before repairs

- Submit warranty claims promptly within specified timeframes

Extended Warranty Considerations:

Evaluate extended warranty offerings critically:

- Compare extended warranty cost vs. out-of-warranty repair typical costs

- Assess likelihood of failures based on component quality and usage

- Review warranty coverage exclusions and limitations carefully

- Consider self-insuring if internal capabilities strong

- Factor in organization’s risk tolerance and budget predictability preferences

Creating a Sustainable Maintenance Program

Successful long-term maintenance requires organizational commitment, trained personnel, adequate resources, and continuous improvement mindset.

Staffing and Responsibility Assignment

Primary Maintenance Coordinator:

Designate one person with ultimate maintenance responsibility:

- Schedule and verify completion of all routine maintenance tasks

- Maintain documentation and service records

- Coordinate professional service provider relationships

- Monitor display performance and identify emerging issues

- Train additional staff members on maintenance procedures

- Report maintenance metrics to organizational leadership

Backup Maintenance Personnel:

Train multiple staff members ensuring coverage during absences:

- At least three people capable of daily cleaning and inspection

- Minimum two people trained on weekly system health checks

- One backup person familiar with troubleshooting procedures

- Document procedures clearly enough for unfamiliar staff emergency coverage

Professional Development:

Invest in ongoing maintenance training:

- Attend manufacturer-provided training sessions and webinars

- Subscribe to industry publications and online forums

- Participate in user groups for knowledge sharing

- Cross-train with other departments (IT, facilities) for broader expertise

- Update procedures as technology and best practices evolve

Budget Planning and Resource Allocation

Annual Maintenance Budget Components:

Consumable Supplies:

- Microfiber cloths (replace monthly): $120/year

- Cleaning solutions and disinfectants: $300/year

- Compressed air and specialized tools: $150/year

- Replacement filters and parts: $200/year

- Total Supplies: $770/year

Labor Allocation:

- Daily tasks (10 min/day): 40 hours/year

- Weekly tasks (1 hour/week): 52 hours/year

- Monthly tasks (3 hours/month): 36 hours/year

- Quarterly tasks (4 hours/quarter): 16 hours/year

- Total Labor: 144 hours/year ($3,600 at $25/hour)

Professional Services:

- Annual preventive maintenance: $800

- Emergency repair budget: $1,500

- Software licenses and updates: $1,200

- Total Professional: $3,500/year

Total Annual Maintenance Budget:

- Small display (< 50"): $4,000-5,000

- Standard display (55-65"): $5,000-7,000

- Large display (75-86"): $7,000-10,000

- Extra-large (98"+): $10,000-15,000

Technology Refresh Reserve:

Budget annually for inevitable hardware replacement:

- Commercial displays last 5-7 years with proper maintenance

- Set aside 15-20% of original purchase price annually

- Example: $15,000 display = $2,250-3,000/year reserve

- Ensures funds available when replacement necessary

Organizations implementing comprehensive digital recognition programs benefit from structured financial planning supporting long-term sustainability.

Continuous Improvement and Performance Monitoring

Key Performance Indicators (KPIs):

Track metrics demonstrating maintenance program effectiveness:

- Uptime Percentage: Target 99%+ availability during operational hours

- Mean Time Between Failures (MTBF): Industry average 50,000+ hours

- Mean Time To Repair (MTTR): Target resolution within 2 hours for critical issues

- User-Reported Issues: Track frequency and types of problems reported

- Preventive vs. Reactive Maintenance Ratio: Target 80% preventive, 20% reactive

- Total Cost of Ownership: Track all expenses against budget

Quarterly Program Review:

Conduct structured reviews evaluating program effectiveness:

- Analyze maintenance metrics and identify trends

- Review incident reports for recurring problems

- Assess whether staffing and resource allocation adequate

- Evaluate professional service provider performance

- Update procedures based on lessons learned

- Adjust budget allocations for upcoming quarter

Conclusion: Protecting Your Investment Through Proactive Care

Touchscreen displays represent significant investments in institutional recognition, visitor engagement, and organizational identity. Structured maintenance programs protect these investments while ensuring optimal performance, professional appearance, and maximum lifespan. Organizations implementing comprehensive cleaning protocols, preventive maintenance schedules, and professional support relationships report dramatically lower total cost of ownership while delivering superior visitor experiences.

The maintenance strategies outlined in this guide provide actionable frameworks for organizations of all sizes, from small installations to complex multi-display networks. Whether managing campus orientation touchscreens, athletic recognition displays, or donor walls, these best practices ensure your digital recognition systems continue engaging visitors effectively for years to come.

Key Success Factors:

- Establish and follow consistent daily, weekly, and monthly maintenance schedules

- Use only approved cleaning products and procedures for your specific touchscreen technology

- Document all maintenance activities thoroughly for warranty compliance and trend analysis

- Invest in professional services for complex issues and preventive care beyond internal capabilities

- Train multiple staff members ensuring coverage and knowledge continuity

- Budget adequately for ongoing maintenance and eventual technology refresh

- Monitor performance metrics identifying issues before they impact visitor experience

Ready to implement professional-grade touchscreen maintenance for your digital recognition displays? Contact Rocket Alumni Solutions for expert guidance on maintenance best practices, professional service options, and comprehensive care programs ensuring your displays deliver exceptional performance and reliability for years to come.