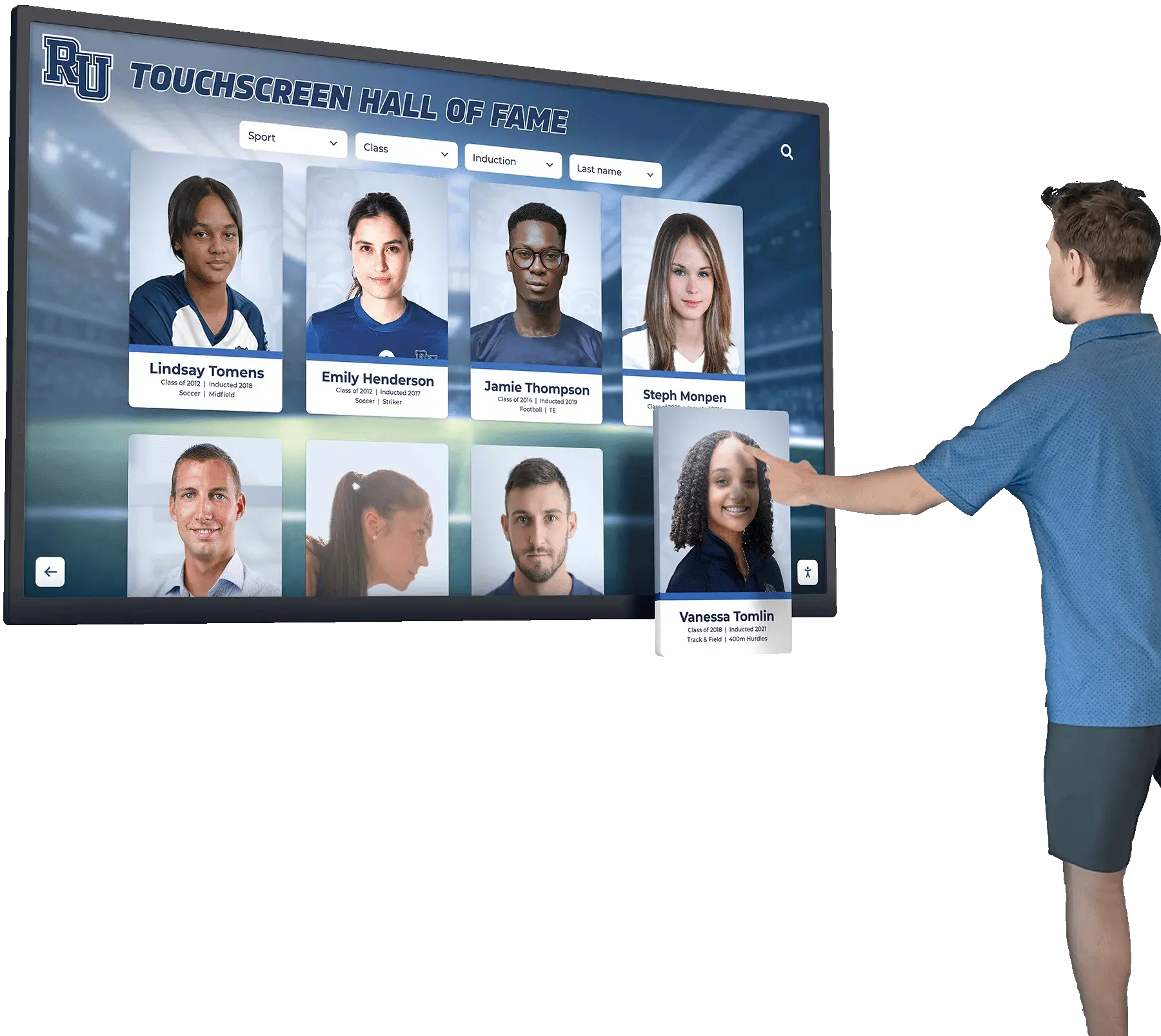

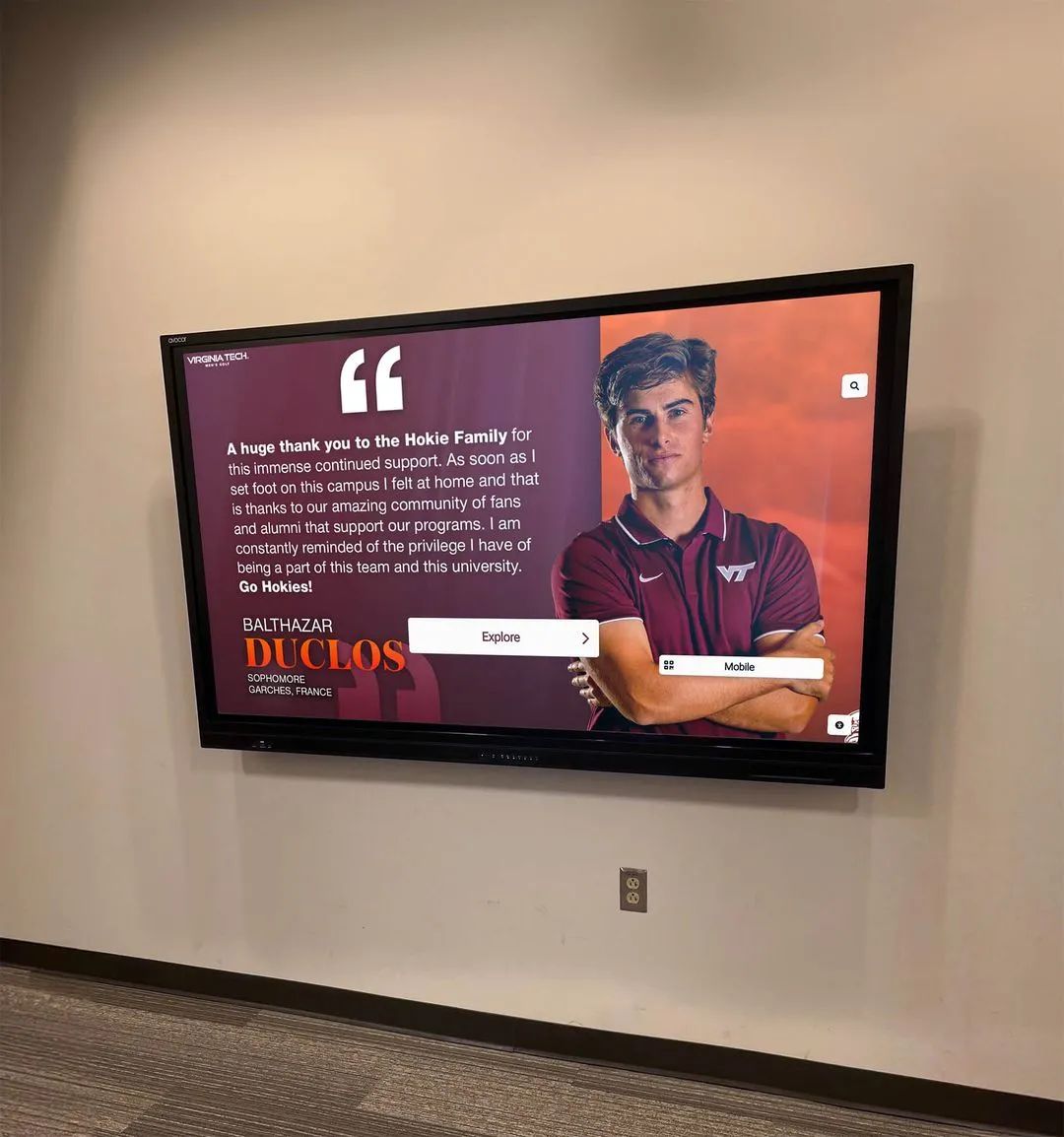

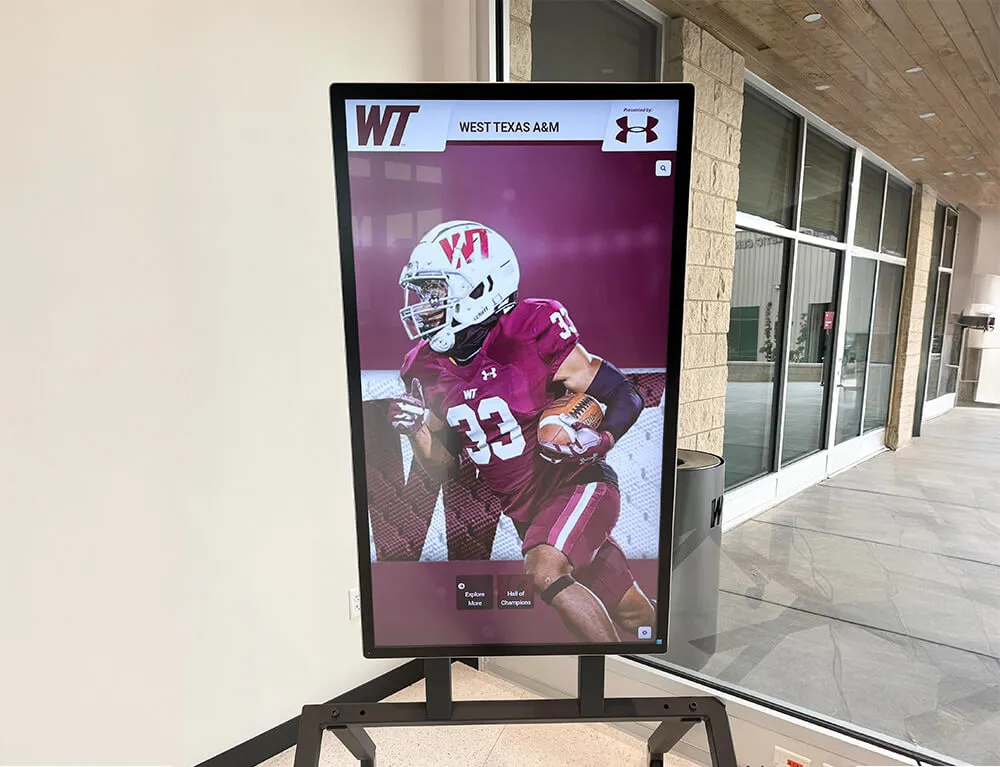

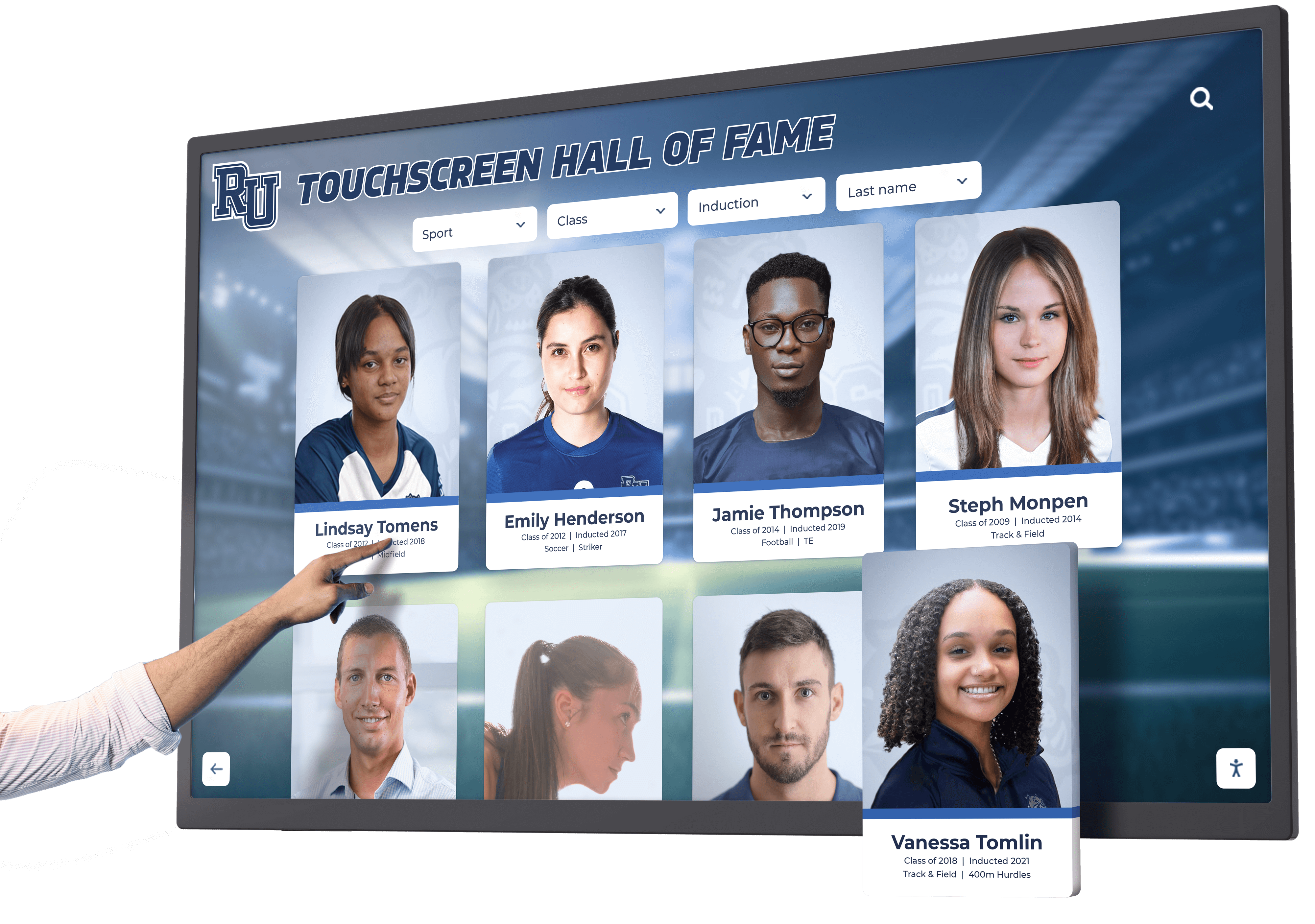

Digital recognition displays transform how schools, universities, organizations, and clubs celebrate achievements. These interactive touchscreen systems enable visitors to explore comprehensive halls of fame, browse athletic records, discover alumni accomplishments, and connect with institutional history in ways traditional plaques and trophies never could. Yet organizations that invest thousands of dollars in recognition technology sometimes struggle to keep systems operating reliably long-term.

The difference between displays that deliver value for a decade versus those that become frustrating maintenance burdens often comes down to establishing proper care routines from day one. Proactive maintenance prevents the majority of issues before they occur, while understanding basic troubleshooting resolves problems quickly without expensive service calls or extended downtime. This guide draws on insights from schools and organizations managing hundreds of installations nationwide, distilling best practices that ensure your digital recognition displays continue impressing visitors and honoring achievements for years to come.

Understanding Your Digital Recognition Display System

Before diving into maintenance procedures, understanding the components that make up your digital recognition system helps you identify where problems originate and how to address them effectively.

Core System Components

Display Hardware: The touchscreen monitor represents the most visible component—typically a commercial-grade LCD or LED panel with touch-sensing capability. These displays range from 43 inches to 86 inches or larger, designed for continuous operation in public spaces. Unlike consumer televisions, commercial displays include features like longer warranty coverage, higher brightness for varied lighting conditions, and thermal management systems supporting 24/7 operation.

Computing Module: Behind or inside the display, a computing module runs the software managing content and user interactions. This might be an integrated system-on-chip (SoC) built into the display, a separate media player, or a full computer depending on your specific implementation. The computing module processes touch inputs, retrieves content, manages animations, and handles all software functions visitors experience.

Network Connectivity: Most recognition displays connect to your network via Ethernet cable or Wi-Fi, enabling content updates, remote management, software patches, and cloud synchronization. Network connectivity allows administrators to modify profiles, add new inductees, or refresh content without physically accessing displays. Some systems operate offline after initial content download, but most benefit from continuous connectivity.

Content Management System: The software platform managing your recognition content—profiles, photos, videos, and organizational structure—typically runs in the cloud with local caching on the display. Solutions like Rocket Alumni Solutions provide intuitive interfaces for creating and updating content that automatically synchronizes to physical displays and web portals.

Mounting Hardware: Wall mounts, floor stands, or custom enclosures provide physical support and positioning for displays. Quality mounting hardware accounts for display weight, allows proper ventilation, positions screens at appropriate viewing heights, and secures expensive equipment against theft or accidental damage.

System Operating Environment

Understanding environmental factors affecting your displays helps prevent damage and optimize performance:

Temperature Considerations: Commercial displays operate reliably within specific temperature ranges—typically 32°F to 104°F (0°C to 40°C). Locations with poor ventilation, direct sunlight exposure, or proximity to heating vents can exceed safe operating temperatures, shortening hardware lifespan and causing unexpected failures. Ensure adequate ventilation around displays with minimum clearances specified by manufacturers—typically 2-4 inches on all sides.

Humidity and Moisture: While most displays tolerate normal indoor humidity levels, excessive moisture from nearby kitchens, locker rooms, or poor building envelope performance can damage electronics and touchscreen components. Monitor condensation issues particularly in locations where temperature differentials cause moisture accumulation. Avoid installing displays where they might encounter splashing water or high humidity environments exceeding 80% relative humidity.

Dust and Particulate Matter: Airborne particles accumulate on screens, clog ventilation systems, and infiltrate electronics. High-traffic areas, locations near outside doors, gymnasiums with chalk dust, or facilities with poor air filtration require more frequent cleaning. Understanding your environment’s dust levels helps establish appropriate maintenance schedules preventing buildup that degrades performance or appearance.

Lighting Conditions: Direct sunlight creates screen glare making content difficult to view while generating heat that stresses display components. Evaluate lighting throughout the day and across seasons—morning sun angles differ from afternoon, and tree coverage varies between summer and winter. Position displays perpendicular to windows when possible, or utilize window treatments controlling problematic light.

Daily and Weekly Maintenance Routines

Establishing consistent basic maintenance routines prevents the majority of issues while keeping displays looking professional and performing optimally.

Daily Visual Inspection

Quick Morning Check: Develop a habit of visually inspecting displays at the beginning of each day. Look for obvious issues including screen powered on and displaying content properly, touchscreen responding to interaction, no physical damage or vandalism, proper mounting security, and ventilation areas clear of obstructions. This 30-second check identifies problems immediately rather than discovering issues when visitors complain hours or days later.

Attention to Detail: During daily inspections, note any changes in display behavior—unusual sounds from fans or cooling systems, screen brightness appearing dimmer than normal, response lag when touching interface elements, or content that hasn’t updated as scheduled. Early detection of developing problems allows proactive intervention before complete failures occur.

Screen Cleaning Protocol

Touchscreens accumulate fingerprints, smudges, dust, and grime from constant visitor interaction. Proper cleaning maintains professional appearance and ensures responsive touch performance.

Cleaning Frequency: High-traffic installations receiving 200+ daily touches require cleaning 3-4 times weekly or even daily during peak seasons. Moderate-traffic displays need cleaning 1-2 times weekly. Low-traffic installations may require only weekly or biweekly cleaning. Adjust frequency based on visible cleanliness and your specific environment.

Proper Cleaning Materials: Never use ammonia-based glass cleaners, alcohol, abrasive cleaners, paper towels, or rough cloths that can damage touchscreen coatings. Instead, utilize microfiber cloths specifically designed for electronics, distilled water or screen-safe cleaning solutions, and gentle wiping motions. Many touchscreen manufacturers provide approved cleaning solutions—check documentation or contact your display vendor for recommendations.

Effective Cleaning Procedure: Power off displays before cleaning when possible to prevent accidental touch inputs and make smudges more visible against dark screens. Lightly dampen (never soak) microfiber cloth with approved cleaning solution. Wipe screen gently using consistent horizontal or vertical strokes, avoiding circular motions that spread oils. Use dry microfiber cloth to buff away any streaks or remaining moisture. Clean from top to bottom to prevent drips onto already-cleaned areas.

Frame and Housing Cleaning: While focusing on screens, don’t neglect surrounding frames, bezels, and housing that also accumulate dust and grime. Wipe these surfaces using slightly dampened cloths, being careful to avoid moisture entering ventilation openings or gaps between screen and frame. Clean appearance matters—dirty frames detract from even pristine screens.

Ventilation and Dust Management

Weekly Ventilation Inspection: Examine air intake and exhaust vents ensuring they remain clear of dust, debris, or obstructions. Use compressed air or soft brushes to remove accumulated dust from vent openings—working carefully to avoid pushing debris deeper into equipment. Proper airflow prevents overheating that shortens component lifespan and causes thermal shutdowns.

Surrounding Area Maintenance: Keep areas around displays clear of materials blocking airflow—papers, decorations, furniture positioned too close, or storage items stacked near equipment. Maintain manufacturer-specified clearances ensuring adequate air circulation. Consider the full airflow path from intake through exhaust, avoiding situations where displays effectively breathe their own hot exhaust air.

Monthly and Quarterly Maintenance Tasks

Beyond daily attention, scheduled monthly and quarterly maintenance addresses less obvious but equally important system health factors.

Software and Content Updates

Monthly Content Review: Schedule regular reviews ensuring recognition content remains current and accurate. Add new inductees, update changed biographical information, verify that upcoming events are properly featured, and remove or archive outdated materials. Content that grows stale reduces visitor engagement—monthly attention keeps displays fresh and relevant.

System Software Updates: Check for available software updates from your content management platform and operating system. Many platforms like digital recognition systems deliver automatic updates, but verify successful installation and test functionality afterward. Updates typically include security patches, performance improvements, bug fixes, and new features enhancing user experience.

Testing After Updates: Never assume updates installed successfully without testing. Interact with displays verifying touch responsiveness, content loads properly, navigation functions correctly, and all features work as expected. Test less-frequently used functions like search, filtering, and video playback that might reveal update-related issues.

Deep Cleaning and Detailed Inspection

Quarterly Deep Clean: Every three months, conduct thorough cleaning beyond routine screen wipes. This includes carefully cleaning ventilation systems using compressed air or vacuum with soft brush attachments, wiping down entire enclosures and mounting hardware, cleaning areas behind or beneath displays where dust accumulates, and inspecting cables for damage, wear, or loose connections.

Connection Verification: Check all cable connections ensuring they remain secure—power cables, network connections, HDMI or display port cables, and USB connections if present. Verify cables aren’t kinked, pinched, or showing signs of wear from stress or movement. Replace any damaged cables immediately to prevent intermittent issues or complete failures.

Touch Calibration Check: Verify touchscreen accuracy by testing interaction at screen corners and edges where calibration drift sometimes manifests. If responses seem slightly offset from where you touch, consult your system documentation about calibration procedures or contact technical support for guidance.

Troubleshooting Common Issues

Even with excellent maintenance, occasional problems occur. Understanding how to diagnose and resolve common issues minimizes downtime and reduces reliance on technical support.

Display Won’t Power On

Systematic Diagnosis: When displays fail to power on, work through potential causes methodically. First, verify the obvious—check that power switches are in the ON position, ensure power cables are fully seated at both display and wall outlet, test wall outlet by plugging in a known-working device, and check for tripped circuit breakers or blown fuses.

If basic power checks pass, examine indicator lights on displays or power supplies. Many displays include LED indicators showing power status, operating mode, or error conditions. Consult documentation explaining what different light patterns indicate. No lights at all typically suggest power supply failure or complete power loss. Lights in unusual patterns may indicate specific error conditions.

Resolution Steps: Try different power outlets ruling out wall outlet issues. Disconnect and reconnect power cables ensuring secure connections. If displays still won’t power on after these steps, contact your vendor’s technical support or qualified service technician. Power supply failures and internal electrical issues require professional diagnosis and repair—attempting DIY repairs on powered electronics risks injury and voids warranties.

Touchscreen Unresponsive or Inaccurate

Common Causes: Touch functionality failures stem from various sources including dirty screens interfering with touch sensing, software crashes or freezes, calibration drift causing offset responses, damaged touchscreen layers from impact or pressure, or connection issues between touch controller and computing module.

Resolution Steps: Begin with thorough screen cleaning following proper procedures described earlier—surprising how often simple cleaning restores function. Restart the display and computing module by power cycling—turn off, wait 30 seconds, power back on. This resolves many software-related touch issues. Test touch response across the entire screen surface identifying whether problems affect the full screen or specific areas. If only certain regions respond incorrectly, touchscreen damage may require professional repair or replacement.

For widespread inaccuracy affecting the entire screen, attempt touchscreen recalibration using procedures specified in your system documentation. Some platforms include calibration utilities in administrative settings, while others require special key combinations during startup. If calibration doesn’t resolve issues or calibration utilities won’t complete successfully, contact technical support—persistent calibration problems often indicate hardware failures requiring component replacement.

Content Not Updating or Displaying Correctly

Network Connectivity Issues: When content fails to update as expected, verify network connectivity first. Check that network cables are securely connected, ensure Wi-Fi connections show active status, test internet access by browsing to known websites from display if possible, and verify that firewalls or content filters aren’t blocking access to your content management system’s servers.

Many recognition platforms like digital showcase solutions require specific network ports remain open. Consult platform documentation or contact support identifying required network access, then work with IT staff ensuring proper configuration.

Cache and Data Issues: Sometimes local data caches become corrupted preventing proper content display. Try forcing a full content refresh using administrative functions in your content management system. If that doesn’t resolve issues, clearing the application cache and allowing fresh data download often fixes display problems. Procedures for cache clearing vary by platform—consult documentation or support resources for specific instructions.

Software Glitches: Intermittent display problems sometimes stem from software bugs or conflicts. Verify you’re running current software versions with all available updates installed. Report persistent issues to your platform vendor including detailed descriptions of symptoms, when problems occur, and any error messages displayed. Quality vendors actively address reported issues through software updates.

Display Overheating or Shutting Down

Thermal Protection: Modern displays include thermal protection systems automatically shutting down equipment when internal temperatures exceed safe thresholds. If displays shut off unexpectedly then power back on after cooling, overheating is likely the culprit.

Causes and Solutions: Check ventilation ensuring intake and exhaust vents remain unobstructed. Verify that surrounding furniture, decorations, or other objects aren’t blocking airflow. Examine installation location for environmental heat sources—direct sunlight, nearby heaters, or confined spaces without air circulation. Consider whether seasonal changes brought warmer ambient temperatures exceeding what displays previously experienced.

If ventilation appears adequate and environment seems reasonable, cooling fans may have failed or intake filters (if present) may be clogged. Some commercial displays include removable air filters requiring periodic cleaning or replacement. Consult manufacturer documentation about filter maintenance. For suspected fan failures, contact service providers—continuing to operate displays with failed cooling risks permanent component damage.

Strange Noises or Visual Artifacts

Interpreting Symptoms: Unusual sounds or display anomalies indicate developing hardware problems requiring attention before complete failure occurs. High-pitched whining or buzzing may suggest capacitor issues or electronic interference. Clicking or ticking sounds could indicate mechanical problems with fans or drives. Visible screen artifacts like flickering, lines, dead pixels, or color distortion point to panel or graphics processing issues.

Appropriate Response: Document symptoms with detailed descriptions, photographs, or videos when possible. Note when symptoms occur—constantly, intermittently, after specific time periods, or in response to particular actions. Contact your vendor’s technical support providing documentation. Don’t ignore warning signs hoping they’ll resolve spontaneously—early intervention often prevents minor issues from becoming expensive failures requiring component replacement.

Preventive Maintenance Scheduling

Establishing consistent preventive maintenance schedules maximizes display lifespan while minimizing unexpected failures and emergency repairs.

Creating Your Maintenance Calendar

Daily Tasks: Assign responsibility for daily visual inspections to specific staff members who work near displays. Create simple checklists ensuring consistent evaluation of key indicators—screen powered and displaying properly, touch functioning, no physical damage, area around display clear and safe. Consider adding display checks to existing daily building inspection routines facilities staff already perform.

Weekly Tasks: Schedule weekly cleaning sessions during low-traffic periods minimizing visitor disruption. Designate trained staff responsible for proper cleaning using approved materials and techniques. Track cleaning completion using simple logs or facility management software creating accountability and documentation.

Monthly Tasks: Establish monthly appointments for deeper maintenance including detailed inspections, cable and connection checks, and software update review. Combine these technical tasks with content review sessions updating recognition information as needed. Monthly maintenance typically requires 30-60 minutes per display depending on system complexity and content volume.

Quarterly Tasks: Plan quarterly deep maintenance during school breaks, holiday closures, or other periods when displays can be taken offline briefly without impacting visitors. These sessions allow thorough cleaning, detailed testing, and any necessary recalibration or configuration adjustments. Budget 1-2 hours per display for comprehensive quarterly maintenance.

Documentation and Record Keeping

Maintenance Logs: Maintain detailed logs documenting all maintenance activities including dates performed, tasks completed, issues identified, cleaning products used, and staff members responsible. Logs reveal patterns helping identify recurring problems, demonstrate due diligence to administrators or insurance providers, guide warranty claims by documenting proper care, and inform future staff after personnel changes.

Issue Tracking: Record all problems encountered with displays even when successfully resolved. Track symptoms observed, troubleshooting steps attempted, solutions that worked, and vendor interactions including support ticket numbers. This historical knowledge base prevents redundant troubleshooting of previously-encountered issues while building institutional expertise about your specific systems.

Warranty and Service Records: Organize warranty documentation, service agreements, and technical support contact information in easily accessible locations. Note warranty expiration dates, covered components, and required maintenance conditions. Track all professional service calls including dates, work performed, parts replaced, and costs incurred. This information proves valuable when evaluating vendor performance, planning budgets, or deciding whether to replace aging equipment.

Extending Hardware Lifespan

Proper maintenance significantly extends the operational life of digital recognition displays, maximizing return on investment while deferring replacement costs.

Optimizing Display Settings

Brightness Management: Running displays at maximum brightness shortens backlight lifespan and wastes energy. Adjust brightness to minimum levels providing comfortable viewing in your specific lighting conditions—usually 50-70% of maximum brightness suffices. Some platforms support automatic brightness adjustment based on ambient light sensors, enabling optimization without ongoing manual intervention. Reducing brightness from maximum to comfortable levels can extend backlight life by 25-40% according to display manufacturers.

Sleep and Power Management: Configure appropriate sleep or low-power modes during hours when facilities are closed and displays serve no visitors. Most recognition systems support scheduled power management reducing energy consumption and component wear during unused periods. However, avoid aggressive power cycling—frequent on/off cycles stress components more than steady operation. Generally, displays operating fewer than 18 hours daily benefit from sleep modes, while 24/7 installations run better staying powered continuously at reduced brightness during off-hours.

Content Optimization: Static images displayed continuously can cause image retention or permanent burn-in particularly on OLED displays and some LCD panels. Implement screen savers, rotating content, or subtle content movement preventing identical pixels from displaying the same colors for extended periods. Quality recognition platforms include built-in content rotation features specifically designed to prevent image retention while keeping displays engaging.

Environmental Protection

Temperature Control: Maintain consistent ambient temperatures within manufacturer specifications. Sudden temperature swings and repeated thermal cycling stress electronic components. If displays are located in spaces without climate control, consider seasonal adjustments to operating schedules, reduced brightness during hot periods lowering heat generation, or even temporary shutdowns during extreme temperature conditions rather than risking heat-related failures.

Surge Protection: Install quality surge protectors or UPS (uninterruptible power supply) units protecting displays from electrical surges, voltage spikes, and power fluctuations. Even brief power anomalies can damage sensitive electronics. Dedicated surge protection represents minimal investment providing significant protection for expensive display equipment. Replace surge protectors every 3-5 years or after major surge events—protection components degrade over time and after absorbing surges.

Physical Protection: While digital displays are more durable than they appear, reasonable precautions prevent accidental damage. Avoid placing items on top of displays, ensure mounting is secure preventing falls, educate users to touch gently rather than pounding screens, consider protective overlays in high-risk environments, and position displays away from sports equipment, moving carts, or other physical hazards.

Planning for Eventual Replacement

Typical Hardware Lifespan: Commercial displays with proper maintenance typically operate reliably for 7-10 years or 50,000-70,000 hours of operation. Factors affecting lifespan include usage hours, environmental conditions, maintenance quality, and initial hardware quality. Budget for eventual replacement rather than expecting indefinite operation. Some components like touchscreen overlays may require replacement before displays themselves fail.

Monitoring Performance Degradation: Watch for gradual performance decline indicating approaching end-of-life including progressive brightness reduction, increasing boot or response times, more frequent glitches or crashes, unusual noises or behaviors, or repair costs approaching replacement costs. Plan replacements proactively during budget cycles rather than emergency replacements after complete failures.

Technology Refresh Cycles: Beyond hardware longevity, consider technology advancement when planning replacements. Displays installed 7-10 years ago use older LCD technology with lower resolution, reduced brightness, and inferior touch sensing compared to current models. Software platforms may also deprecate support for older hardware. Factor both hardware condition and technology currency into replacement timing decisions.

Working with Technical Support and Service Providers

Even with excellent in-house maintenance, some situations require professional technical support or service providers. Knowing when and how to engage support ensures efficient problem resolution.

When to Contact Support

Clear Support Escalation: Establish clear criteria for when internal staff should escalate issues to technical support including problems persisting after standard troubleshooting, hardware failures suspected (power issues, touch failures, display defects), software issues beyond basic troubleshooting capability, network or connectivity problems requiring server-side configuration, or any situations where continued troubleshooting risks causing additional damage.

Effective Support Requests: When contacting support, provide comprehensive information accelerating diagnosis and resolution. Include specific symptoms and error messages observed, troubleshooting steps already attempted, when problems first appeared, frequency and consistency of issues, system information (display model, software version, operating system), environmental details (location, temperature, recent changes), and photos or videos demonstrating problems when applicable.

Quality vendors like specialized touchscreen platform providers maintain responsive support teams familiar with common issues and able to resolve most problems through remote assistance, detailed troubleshooting guidance, or configuration adjustments.

Managing Service Relationships

Preventive Service Agreements: Consider preventive maintenance agreements with vendors or qualified service providers offering periodic on-site inspections, preventive maintenance including deep cleaning and testing, priority support response, discounted repair rates, and replacement hardware access. While adding ongoing costs, service agreements provide peace of mind and often cost less than emergency service calls when problems arise unexpectedly.

Service Provider Selection: If your hardware vendor doesn’t provide service or you need local support, research qualified service providers before emergencies occur. Verify experience with commercial displays and touchscreen systems, ask for references from similar installations, understand service response times and costs, clarify what equipment and expertise they maintain on-hand, and establish service relationships before needing emergency assistance.

Warranty Management: Understand warranty coverage terms including duration and covered components, maintenance requirements to maintain warranty validity, exclusions for certain types of damage or misuse, claim procedures and required documentation, and whether coverage includes on-site service or requires shipping equipment. Maintain detailed maintenance records demonstrating proper care should warranty claims arise.

Training Staff for Effective Maintenance

Sustainable maintenance programs require proper staff training ensuring consistent application of best practices and efficient problem resolution.

Initial Training Programs

Hands-On Training: New staff responsible for display maintenance need practical hands-on training covering proper cleaning techniques with approved materials, daily inspection procedures and what to look for, basic troubleshooting for common issues, when and how to contact technical support, safety procedures and precautions, and documentation requirements and tools.

Training Documentation: Supplement hands-on training with clear written documentation including photo-illustrated cleaning procedures, troubleshooting flowcharts for common problems, contact information for technical support and service providers, maintenance schedules and checklists, and approved materials and suppliers lists. Accessible documentation supports consistent application of procedures and helps staff refresh their knowledge when needed.

Ongoing Education

Technology Updates: When software updates introduce new features or modify interfaces, brief training sessions help staff understand changes and continue managing systems effectively. When hardware is upgraded or replaced, familiarize staff with any new capabilities, maintenance requirements, or operational differences. As vendors release best practice updates or new maintenance recommendations, share this information with responsible staff.

Cross-Training: Avoid single-person dependencies by cross-training multiple staff members on maintenance procedures. Personnel changes are inevitable—comprehensive cross-training ensures continuity when primary maintenance staff transition to new roles. Designate primary and backup staff for all maintenance functions creating resilience against absences, turnover, or increased workload.

Conclusion: Investing in Long-Term Success

Digital recognition displays represent significant investments delivering value for decades when properly maintained. The difference between systems that consistently delight visitors versus frustrating maintenance burdens comes down to establishing comprehensive maintenance routines, implementing preventive care strategies, training staff effectively, and responding promptly when issues arise.

Effective maintenance doesn’t require extensive technical expertise—mostly consistent attention to basic care, systematic inspections, and proper troubleshooting when problems occur. Organizations following the practices outlined in this guide report fewer hardware failures, reduced total maintenance costs, extended equipment lifespan, better user experiences with reliable systems, and lower stress for staff managing displays.

Key Principles for Maintenance Success:

- Establish consistent daily and weekly inspection and cleaning routines

- Implement preventive maintenance schedules addressing issues before they become failures

- Document all maintenance activities creating institutional knowledge

- Train staff comprehensively with hands-on practice and clear written procedures

- Know when to escalate issues to professional technical support

- Optimize operating conditions and settings maximizing hardware longevity

- Plan proactively for eventual hardware refresh rather than emergency replacements

Ready to implement a digital recognition system designed for easy maintenance and long-term reliability? Modern solutions like Rocket Alumni Solutions provide not only intuitive content management and engaging visitor experiences but also robust platforms engineered for reliable operation and straightforward maintenance. Our team provides comprehensive implementation support, detailed maintenance guidance, responsive technical assistance, and ongoing platform improvements ensuring your recognition displays continue performing excellently year after year.

Your achievements deserve celebration that endures. Proper maintenance ensures digital recognition displays continue honoring accomplishments, engaging communities, and building institutional pride reliably for years to come.